As of April 1, Making Stories is closed. Thank you for your support all these years!

As of April 1, Making Stories is closed. Thank you for your support all these years!

Spinning Fiber

Notions & Gifts

Books, Magazines & Patterns

About Us

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

Our Sustainability Pledge

Our Blog

Our Podcast

The Making Stories Collective

Why Is Superwash Yarn Not Sustainable?

May 20, 2020 5 min read 4 Comments

Last week, Claire dove into the world of single-flock yarn - beautiful, small batch fibres. Today, I'll be looking at something that is a lot more easily found: superwash yarn. More specifically, why exactly is it that superwash yarn is not sustainable?

To answer that, let's take a little step back and revisit what 'superwash' actually is:

What is superwash?

Superwash yarn and fibre (yes, there's also superwash fibre for the spinners out there!) has undergone an additional processing step after it's been spun to make it shrink-resistant and therefore machine-washable.

Wool shrinks because it felts: The tiny scales that contribute to so much of the awesomeness of wool (They trap air to keep you warm! They increase the surface area of the fibre so that it can hold more water!) have a strong tendency to link arms when rubbed against each other. As they hold on to each other, the fibre becomes smaller and smaller, denser and denser - it felts.

So to make yarn machine-washable, you have to get rid of the scales. There are - generally - two ways to do this: You can either strip the scales off the fibre, or you can coat it in something to flatten the scales.

The most common superwash process - used for approx. 75% of all superwash-treated wool - is the Chlorine-Hercosett process which combines both techniques. As a first step, the fibre is chlorinated, i.e. treated with chlorine gas or a chlorine solution, to get rid of the natural 18-MEA (18-methyl eicosanoic acid, a fatty acid that helps to repel water) coating the fibre and to etch away the edges of the scales. In the second step, a polyamide-epichlorohydrin resin - more commonly known as Hercosett 125 - is applied to the fibre.

The removal of 18-MEA and the edges of the scales helps with the distribution of the resin; the application of the resin creates the 'superwash' coat that helps prevent felting and shrinkage. The resin itself is a type of plastic which is why you'll also find superwash yarn described as 'plastic-coated'.

What are the advantages and disadvantages of superwash yarn?

The yarn that comes out of this process has a few distinct advantages:

-

It's machine-washable: This one is by now obvious: Because the yarn has gone through the superwash process, it can be washed in the machine or by hand at higher temperatures and wrung out without fear of shrinking or felting.

-

It takes dye beautifully: All of you will know the beautiful deep colors or speckled goodness that indie-dyers are able to achieve on superwash yarns. This happens because superwash yarns can absorb more dye than non-superwash yarns due to the de-scaling and smooth resin-coated surface!

-

It's very soft: The removal of the scales and coating of the fibre in resin results in a much smoother and therefore softer surface than most non-superwash yarns can offer.

It also has a range of disadvantages:

-

It's not elastic: If you've knit a sweater in superwash yarn, you will have noticed that it's not easy to coax it back into shape when it's been washed. This is because the yarn itself loses much of its elasticity - its 'springiness', if you will, it's ability to hold and spring back into the shape you intended it to - as the individual fibres are not able to cling to each other anymore.

-

It's not warm: The scales on untreated wool fibre trap air, and air equals warmth. They are the reason your woollens keep you warm even on the coldest days, and when you remove them, you also remove the yarn's potential to warm you.

-

It doesn't repel water: If you've gotten into a rain shower with only a (non-superwash) sweater on, you might have noticed that you don't get as wet as fast, right? Wool has natural water-repellent properties, and as you remove both the chemical and physical ones (hello 18-MEA from up above! hello scales!) during the superwash process, a superwash yarn won't repel water as well as an untreated one.

In addition to these mostly fabric-related disadvantages, let's talk about the proverbial bull in a china shop here: Superwash yarns are not sustainable. Full stop.

Why is superwash yarn not sustainable?

-

It uses hazardous chemicals: Both the chlorine and the chemicals used to create the polyamide-epichlorohydrin resin are highly toxic. In addition, during the chlorination process, the chlorine reacts with the carbon-based (i.e. organic) compounds present in wool, creating adsorbable organohalogens (AOX), another group of toxins. The production process itself has the risk of exposing employees to these toxic chemicals, and the wastewater resulting from it contains extremely high levels of AOX. (So much so that most wastewater treatment facilities in the US don't accept it.)

-

It uses more water and energy: If you make a yarn superwash, you add in another process step in the - already pretty long - production chain of yarn. More process steps = more water and energy used in the entire process.

-

It sheds microplastic: If you've knit a pair of socks in superwash yarn, and you've washed them quite often, you might notice that the smooth coating wears off. The plastic that covers the yarn's surface slowly but surely detaches itself from it and gets washed down the drain as microplastic particles.

-

It's not biodegradable: Well, it's wool coated in plastic. Wool itself is beautifully compostable, but with the plastic coating on top, it's not anymore. As with all plastics, it can take a long - a very long - time to degrade, shedding harmful chemicals and polluting the environment until then.

To sum it up: The traditional superwash process used by most superwash yarns is not sustainable at all. It uses highly harmful chemicals, is potentially unsafe for the workers, definitely unsafe for the environment, and results in a non-biodegradable product that might sit on our earth for the foreseeable future.

What about that superwash yarn in my stash though?

This might sound counterintuitive now, but: don't throw it away! It's already been produced, so throwing it out - maybe even in the trash - would just create more waste. Instead, use it to create something beautiful or give it to someone who might do so. Using up what we have is a cornerstone of sustainability!

Are there any sustainable superwash-like options?

Glad that you asked! I'll be taking a look at alternative superwash processes that have been developed over the last years next week to see if there are any superwash-like options that are more sustainable. I'd love to invite you to check back in next Wednesday for that post!

4 Responses

coatingsnwcomplete

September 30, 2022

This is the perfect web site for anybody who really wants to find out about this topic. You understand a whole lot its almost tough to argue with you (not that I really would want to?HaHa). You definitely put a new spin on a topic that’s been discussed for many years. Excellent stuff, just excellent!

Janet Sullivan

March 30, 2022

The other ‘advantage’ of superwash process – related to ‘softness’ I suppose, is that it is less irritating to people who are sensitive or allergic to wool. I sell superwash yarn in my store – which otherwise is dedicated to natural and sustainable yarns and fibers. I have been uneasy about the whole superwash process for years and have tried to minimize my offerings. Would you kindly provide your specific sources for the information and conclusions you have presented in this blog, it would be very helpful to me. Also, do you know of commercially available alternate shrink-resistance yarns or fibers? I have recently heard of ‘EasyWash’ wool, but as a trademarked term it is hard to find in relationship to yarn.

Thanks!

Kteni Smith

May 20, 2020

I am looking forward to seeing next week’s post. This topic pokes and prods at me. There is more connected to it than sustainability; people are connected to it. Livelihoods are connected to it. Education, as always is the way to solving, and to resolving to do better.

Leave a comment

Comments will be approved before showing up.

Also in Blog

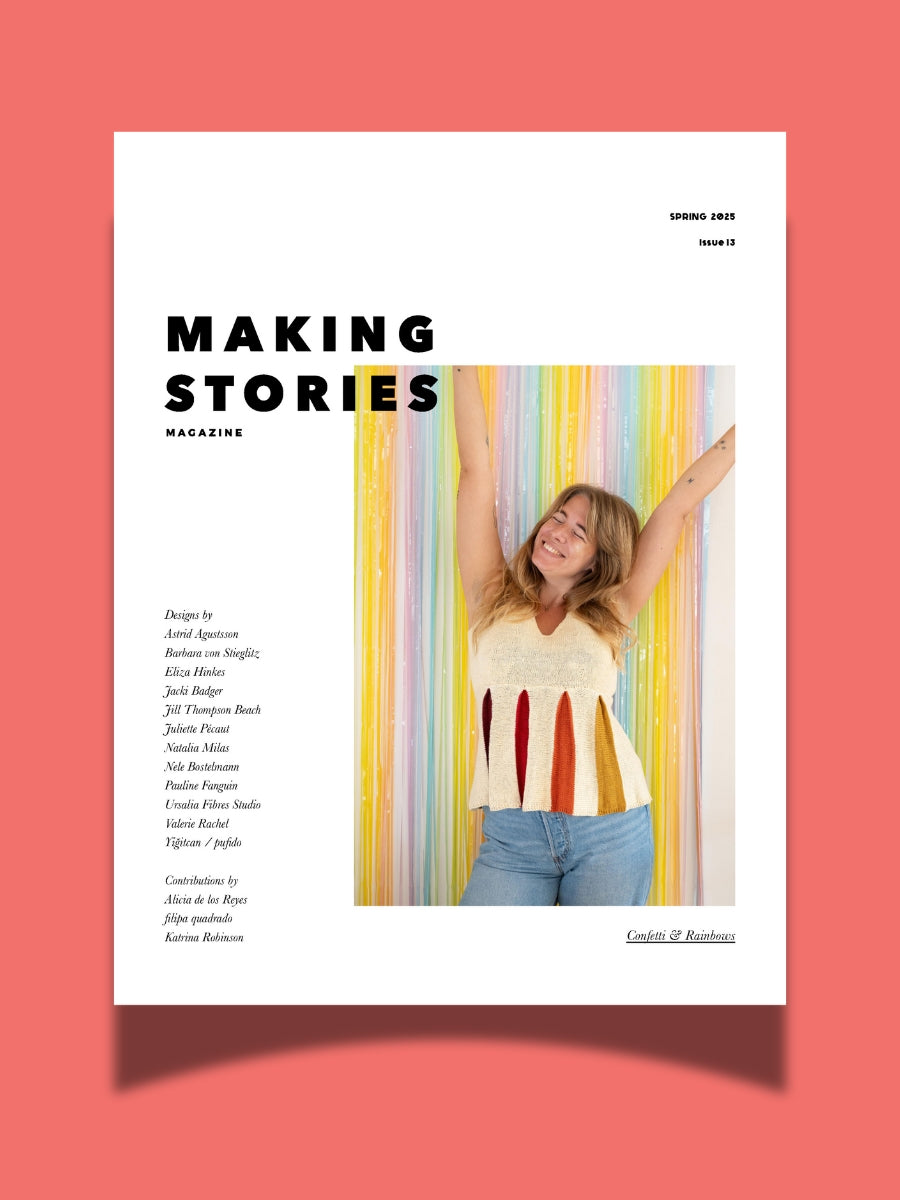

Issue 13 – Confetti & Rainbows | Official Pattern Preview

February 12, 2025 13 min read

Hi lovelies! The sun is out here in Berlin, and what better day to talk about one of the most joyful issues we've ever done than a brilliant sunny winter day – meet Issue 13, Confetti & Rainbows!

In Issue 13 – our Spring 2025 Issue – we want to play! Confetti and rainbows, unusually and unconventionally interpreted in 12 new knitwear designs – a journey through color, shapes, texture and materials.

Confetti made out of dried flowers, collected over months from bouquets and the road side. Sparkly rainbows, light reflecting. Gentle textures and shapes, echoing the different forms confetti can take. An unexpected rainbow around the corner, on a brick wall, painted in broad strokes.

New Look, Same Heart: The Story Behind Our Delightful Rebrand

January 16, 2025 4 min read 1 Comment

Hi lovelies! I am back today with a wonderful behind-the-scenes interview with Caroline Frett, a super talented illustrator from Berlin, who is the heart and and hands behind the new look we've been sporting for a little while.

Caro also has a shop for her delightfully cheeky and (sometimes brutally) honest T-Shirts, postcards, and mugs. (I am particularly fond of this T-Shirt and this postcard!)

I am so excited Caro agreed to an interview to share her thoughts and work process, and what she especially loves about our rebrand!

Thoughts on closing down a knitting magazine

November 19, 2024 12 min read 1 Comment

Who Is Making Stories?

We're a delightfully tiny team dedicated to all things sustainability in knitting. With our online shop filled with responsibly produced yarns, notions and patterns we're here to help you create a wardrobe filled with knits you'll love and wear for years to come.

Are you part of the flock yet?

Sign up to our weekly newsletter to get the latest yarn news and pattern inspiration!

Susan Woolner

December 04, 2022

I have been wearing wool sweaters that are machine washable for years and only just found out about the properties of machine washable wool. Since moving to Scotland, that produces a lot of wool and cashmere sweaters, and which I have been buying are NOT machine washable. However this is not really a problem as although I have to gently hand wash them in luke warm water, and lay them flat to dry, they stay beautifully soft and fit me perfectly for years, and I know I am not wearing plastic. BUY hand wash wool only.