As of April 1, Making Stories is closed. Thank you for your support all these years!

As of April 1, Making Stories is closed. Thank you for your support all these years!

Spinning Fiber

Notions & Gifts

Books, Magazines & Patterns

About Us

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

Our Sustainability Pledge

Our Blog

Our Podcast

The Making Stories Collective

Superwash & Non-Superwash - the Indie Dyer Perspective | Karida Collins, Neighborhood Fiber Co.

July 16, 2020 4 min read

Back in May, when we published our first two articles on superwash yarn where we explored why superwash yarn is not sustainable and looked for more sustainable superwash options we received quite a few comments over on Instagram asking 'But what about the indie dyers?'

It's true - a lot, if not most, indie dyers dye on superwash bases. Superwash yarn takes dye beautifully, and it's still very high in demand, so it doesn't come as a surprise that it constitutes a large portion of the indie dyed yarn market!

Not being an indie dyer myself, I definitely didn't feel qualified to comment on why indie dyers might choose superwash over non-superwash and what the difference in dyeing and selling is.

So I reached out to a few different indie dyers and I'm so excited to share the perspectives of Karida from Neighborhood Fiber Co. and Bethany from Woolberry Fiber Co. with you in today's and next week's blog posts, starting with Karida today!

Karida Collins founded Neighborhood Fiber Co. in 2006. Fast forward 14 years and she and her team not only dye beautifully bright yarn inspired by urban landscapes, but also run a studio store (closed right now due to Covid-19) and offer a vast range of knitting- and not-so-much-knitting-related notions (hello commUNITY T-Shirts!).

Karida has raised almost 100,000 USD for her NFC Momentum Fund, a donor-advised charitable fund at the Baltimore Community Foundation, through which she supports a variety of organizations working for justice, empowerment and equality in Baltimore, where she lives and works. Talk about a force for good!

Here's her perspective on offering both superwash and non-superwash yarns:

If I'm not mistaken, you recently started to introduce non-superwash bases to your portfolio (Rustic Fingering comes to mind!). Would you be able to share a little bit about the why behind that decision?

The decision to add some non-superwash yarns was largely a response to demand. More and more customers are interested in wool yarn that feels woolly and behaves like wool. I have also started to move away from the traditional superwashing process [ed. note: the Hercosett-Chlorine process] because of its impact on the environment.

It's the same reason that I'm slowly eliminating nylon from all of the yarns and why we've made a conscious effort to decrease our water usage.

I'm also really curious about the how. Was it difficult to find a non-superwash yarn supplier or mill that you felt comfortable working with? What were some of the obstacles or challenges you encountered when you set out on this path?

I work with a mill that is very responsive to my needs. So for me, the hardest part was just explaining it to them. They were very confused about why I would want non-superwash yarn. However, my experience is largely influenced by my ability to buy 1000 pounds of yarn at a time. It's easier to get what you want when you can buy a lot at a time. This factor was VERY important when I started to make the transition to GOTS Certified machine-washable wool as a replacement for superwash. The minimum order was 900 pounds of wool.

I'm not a yarn dyer myself, but I've heard from multiple indie dyers that dyeing on superwash and non-superwash is very, very different. From your experience, what are the main differences when working with superwash vs. non-superwash bases?

Because the superwashing process smooths out all of the tiny fibers, it has a sheen to it that non-superwash wool does not. It's also more ready to take up the dye, so it's easier to get brighter, more saturated colors with superwash yarn. You can also be less careful about temperature and agitation with superwash yarn. Because of the possibility of felting, we are more gentle with the non-superwash yarn.

However, as a dyer, if you can dye roving, then you can dye yarn that isn't superwash. It's just a slower process with more gradual dye absorption.

How does, from your experience, superwash vs non-superwash yarn differ in terms of margins and demand from knitters? Does one of them clearly sell better?

The Rustic Fingering yarn is the only base that's fully transitioned in our lineup at this time, and the response really varies. Some people miss the sheen of the superwash yarn, while other people really appreciate the sheepy smell and "stickiness" of the non-superwash yarn.

We're beginning to experiment with a slightly lower micron count wool for the Rustic Fingering that is still non-superwash to see if that gives us back some of the sheen and saturation while maintaining the things we really like about the wool. For people that really want a superwash yarn, we have the Studio Sock, which will remain machine-washable.

How easy is it to find out about the superwash processes your yarn suppliers use?

All of my suppliers have been very forthcoming when I ask questions about their processes or procurement.

Do you have any advice for fellow indie dyers who are exploring either an introduction of non-superwash yarns or maybe even a full switch?

If you have a supplier with whom you have a good working relations, just ask. Even if you can't order enough yarn to make a big minimum for a custom order, there is a chance that other dyers have been asking the same questions. If there's enough interest, a mill may be willing to try something different.

Thank you so, so much for sharing your insights with us, Karida! I learned a lot reading your answers, and I can't wait to get my hands on some Rustic Fingering yarn!

You can find Karida and Neighborhood Fiber Co. over on their website, Instagram (@neighborhoodfiberco), and the NFC Momentum Fund over on GoFundMe.

Leave a comment

Comments will be approved before showing up.

Also in Blog

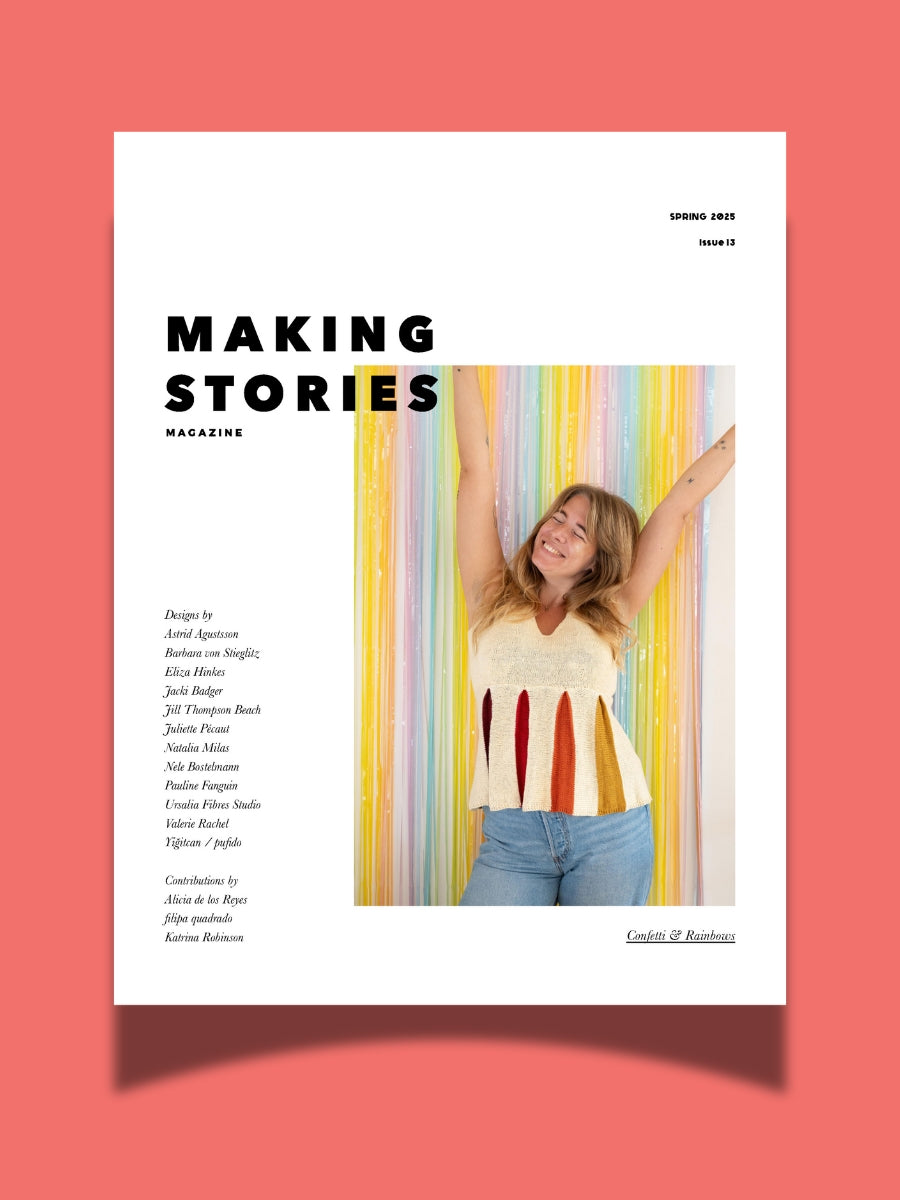

Issue 13 – Confetti & Rainbows | Official Pattern Preview

February 12, 2025 13 min read

Hi lovelies! The sun is out here in Berlin, and what better day to talk about one of the most joyful issues we've ever done than a brilliant sunny winter day – meet Issue 13, Confetti & Rainbows!

In Issue 13 – our Spring 2025 Issue – we want to play! Confetti and rainbows, unusually and unconventionally interpreted in 12 new knitwear designs – a journey through color, shapes, texture and materials.

Confetti made out of dried flowers, collected over months from bouquets and the road side. Sparkly rainbows, light reflecting. Gentle textures and shapes, echoing the different forms confetti can take. An unexpected rainbow around the corner, on a brick wall, painted in broad strokes.

New Look, Same Heart: The Story Behind Our Delightful Rebrand

January 16, 2025 4 min read 1 Comment

Hi lovelies! I am back today with a wonderful behind-the-scenes interview with Caroline Frett, a super talented illustrator from Berlin, who is the heart and and hands behind the new look we've been sporting for a little while.

Caro also has a shop for her delightfully cheeky and (sometimes brutally) honest T-Shirts, postcards, and mugs. (I am particularly fond of this T-Shirt and this postcard!)

I am so excited Caro agreed to an interview to share her thoughts and work process, and what she especially loves about our rebrand!

Thoughts on closing down a knitting magazine

November 19, 2024 12 min read 1 Comment

Who Is Making Stories?

We're a delightfully tiny team dedicated to all things sustainability in knitting. With our online shop filled with responsibly produced yarns, notions and patterns we're here to help you create a wardrobe filled with knits you'll love and wear for years to come.

Are you part of the flock yet?

Sign up to our weekly newsletter to get the latest yarn news and pattern inspiration!