As of April 1, Making Stories is closed. Thank you for your support all these years!

As of April 1, Making Stories is closed. Thank you for your support all these years!

Spinning Fiber

Notions & Gifts

Books, Magazines & Patterns

About Us

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

Our Sustainability Pledge

Our Blog

Our Podcast

The Making Stories Collective

Superwash & Non-Superwash - the Indie Dyer Perspective | Bethany Evans-Brown, Woolberry Fiber Co.

July 22, 2020 5 min read

Last week, we shared Karida Collins' (Neighborhood Fiber Co.) perspective on dyeing and selling superwash and non-superwash yarns in our 'Indie Dyer Perspective' series on superwash - and this week I'm thrilled to welcome another indie dyer I've admired for a long time to these virtual pages: Bethany Evans-Brown from Woolberry Fiber Co.!

Woolberry Fiber Co. is a completely family-owned and -run yarn business: Bethany and her husband Rhys hand-dye all of their yarn while taking care of two little ones - and they just welcomed their first employee to Woolberry Fiber Co.!

They strive to keep the environmental impact of their business as low as possible by reusing water during the dye process, exhausting their dye baths fully, and using recycled and recyclable packaging materials. Plus, 5% of all website purchases go to charity: water, an organization helping to provide clean drinking water to remote tribes and villages around the world.

Woolberry Fiber Co. offers both superwash and non-superwash yarns in their portfolio, and I'm so happy Bethany decided to share her insights on this decision with us!

Over to Bethany:

Your yarn base portfolio is quite equally balanced between superwash and non-superwash yarns. Would you be able to share a little bit about the why behind that decision and how it came about?

For us, it is important to have options for all of our customers. We have some customers who really love superwash and do not feel comfortable knitting and washing with non-superwash. While other customers prefer non-superwash! Our goal is to always have a good amount of each in our shop (right now, we are low on stock due to just returning from maternity leave).

When we started Woolberry, we only offered superwash mainly because I did not know how to dye non-superwash. However, over the years as we have gained greater understanding of the science behind dyeing, we have been able to start incorporating non-superwash into our regular rotation of bases. We hope to have a whole line of non-superwash, breed specific yarns to offer in our shop within the next few years.

I'm also really curious about the practicalities of the how. Was it difficult to find a non-superwash yarn supplier or mill that you felt comfortable working with? What were some of the obstacles or challenges you encountered when you set out on this path?

Finding a good supplier for non-superwash was much more time-consuming and difficult for us. We either found amazing mills that couldn't offer us the quantity we needed or other mills that required us to provide the raw wool that they would spin. It took roughly 3 years to find a mill that fit our needs and allowed us to not only purchase higher quantities of wool but also work on developing custom bases together.

Some of the other challenges we faced were finding a mill that could spin both fine and bulky yarn, offer us an array of options when it came to the actual ply and spin of the yarn, as well as having good relationships with local ranchers so that we did not have to provide our own raw wool, but has the option for us to do that if, in the future, we would like to.

I'm not a yarn dyer myself, but I've heard from multiple indie dyers that dyeing on superwash and non-superwash is very, very different. From your experience, what are the main differences when working with superwash vs. non-superwash bases?

Due to the nature of superwash yarn having a thin coating around it, dyes - specifically acid-based dyes - adhere quite quickly and easily as well as allow you to create the classic speckled skein so many of us in the industry are familiar with. It is also difficult to felt, so it's a great beginner yarn for dyers to experiment with when perfecting their skill.

When dealing with non-superwash, you have to focus a lot more on having the dyes bind with the fibers while not agitating the fibers causing the fibers to shrink or as many refer to as felting. Because of this, many dyers do not feel comfortable with dyeing non-superwash and many others do not have the 'dye style' that works well with non-superwash such as heavily speckled or variegated skeins. Non-superwash works best with semi-solid or very lightly speckled colorways.

How does, from your experience superwash vs non-superwash yarn differ in terms of margins and demand from knitters? Does one of them clearly sell better?

I feel that there is a shift in the industry where non-superwash is gaining traction. However, in my experience, superwash yarn still sells better. It seems many of our customers love our speckled colorways which we produce primarily on superwash bases or are not comfortable washing knitted or crocheted garments with non-superwash in fears it might shrink/felt.

We are actively working on developing more non-superwash bases and educating our customers on how to properly care for their non-superwash garments as well as develop colorway collections that highlight the beauty of non-superwash yarns.

How are your customers connecting with the bases? Do they have a clear preference for superwash vs non-superwash?

We still see much more demand for superwash, but we are hoping to change that so that we can offer a balanced range of superwash and non-superwash. We have just produced a new custom non-superwash base with our mill - Berry Cormo (100% US Cormo) and it sold out within 3 hours of the release. I think offering this more unique non-superwash base really helped our customers become interested in trying out more non-superwash yarns.

How easy is it to find out about the superwash processes your yarn suppliers use?

Truly, it is quite difficult. We had to personally email our yarn supplier to ask about the process. I truly do not think many people understand how the process works.

Do you have any advice for fellow indie dyers who are exploring either an introduction of non-superwash yarns or maybe even a full switch?

I think the best way to start is to find a mill or yarn supplier who has a wide range of non-superwash yarns for you to try out. Learn how to dye them properly, try knitting with them, and then develop colorways that really highlight the beauty of the yarn. Then take your customers on a journey of discovering these bases alongside you. Offer sample packs/release a new range of colorways that are only offered on your non-superwash bases/host a KAL for non-superwash yarns/etc.

With anything in this industry, taking your customers and followers on a journey - telling the story - really allows you to bring new products and new ideas to your shop making that 'risk' of offering a new product and it falling short much smaller.

Thank you so much for sharing your perspective with us, Bethany! I loved learning about the different dye styles that work well with non-superwash vs. superwash yarns and really value the insights on how difficult it was to find a non-superwash supplier!

You can find Bethany and Woolberry Fiber Co. over on their website and Instagram (@woolberryfiberco).

Leave a comment

Comments will be approved before showing up.

Also in Blog

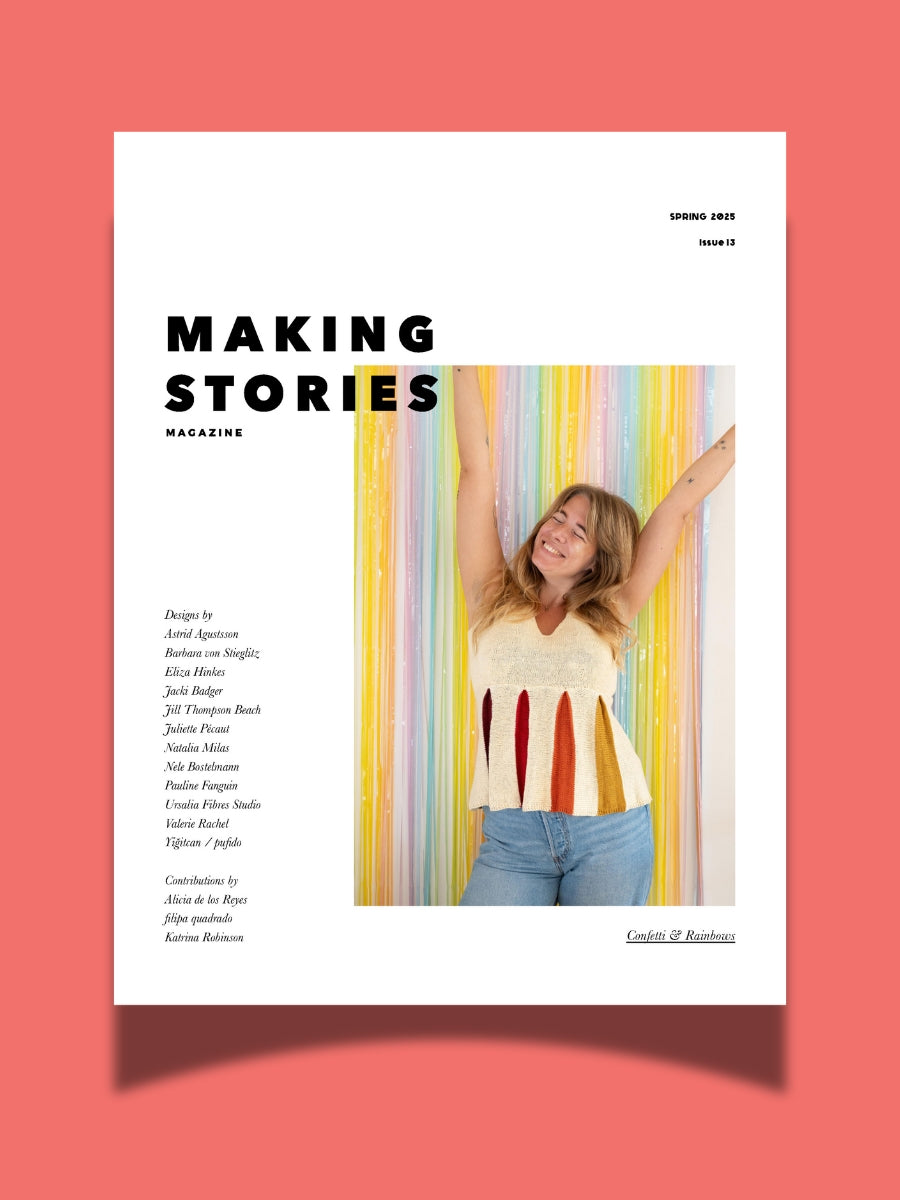

Issue 13 – Confetti & Rainbows | Official Pattern Preview

February 12, 2025 13 min read

Hi lovelies! The sun is out here in Berlin, and what better day to talk about one of the most joyful issues we've ever done than a brilliant sunny winter day – meet Issue 13, Confetti & Rainbows!

In Issue 13 – our Spring 2025 Issue – we want to play! Confetti and rainbows, unusually and unconventionally interpreted in 12 new knitwear designs – a journey through color, shapes, texture and materials.

Confetti made out of dried flowers, collected over months from bouquets and the road side. Sparkly rainbows, light reflecting. Gentle textures and shapes, echoing the different forms confetti can take. An unexpected rainbow around the corner, on a brick wall, painted in broad strokes.

New Look, Same Heart: The Story Behind Our Delightful Rebrand

January 16, 2025 4 min read 1 Comment

Hi lovelies! I am back today with a wonderful behind-the-scenes interview with Caroline Frett, a super talented illustrator from Berlin, who is the heart and and hands behind the new look we've been sporting for a little while.

Caro also has a shop for her delightfully cheeky and (sometimes brutally) honest T-Shirts, postcards, and mugs. (I am particularly fond of this T-Shirt and this postcard!)

I am so excited Caro agreed to an interview to share her thoughts and work process, and what she especially loves about our rebrand!

Thoughts on closing down a knitting magazine

November 19, 2024 12 min read 1 Comment

Who Is Making Stories?

We're a delightfully tiny team dedicated to all things sustainability in knitting. With our online shop filled with responsibly produced yarns, notions and patterns we're here to help you create a wardrobe filled with knits you'll love and wear for years to come.

Are you part of the flock yet?

Sign up to our weekly newsletter to get the latest yarn news and pattern inspiration!