As of April 1, Making Stories is closed. Thank you for your support all these years!

As of April 1, Making Stories is closed. Thank you for your support all these years!

Spinning Fiber

Notions & Gifts

Books, Magazines & Patterns

About Us

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

We're here to help you stitch sustainability into every aspect of your making.

With our carefully curated selection of non-superwash, plastic-free yarns and notions, we have everything you need to get started on your next project - and the one after that.

Here's to a wardrobe of knits we love and want to wear for years to come!

Our Sustainability Pledge

Our Blog

Our Podcast

The Making Stories Collective

What’s the difference between combed top, roving, batts and rolags?

May 08, 2024 5 min read

Learning to spin yarn comes with a huge array of new jargon, and a lot of these terms relate to how the fibre is prepared. Whether animal or plant fibre, there is a variety of ways it can be processed from raw material into something you can spin into yarn. We’re going to look at some of the common formats available to hand spinners, what their characteristics are and the kind of spinning techniques they’re suitable for.

Woollen or worsted?

First up, we need to talk briefly about woollen and worsted preparation. In fibre prep these terms mostly describe the alignment of the individual fibres (or staples), and whether shorter fibres are removed.

While it is tempting to look at woollen/worsted as a binary thing, it’s more of a continuum: a woollen fibre prep has the fibres all jumbled and scrunched up, pointing every which way, while worsted has every individual staple aligned and parallel. Woollen prep is particularly suitable for shorter fibres and gives bouncy, airy yarn. Worsted preparation removes shorter fibres and requires a much longer overall staple length, and when spun worsted style will yield a more compact, sleek yarn with good stitch definition and more durability.

Generally a woollen preparation will call for long-draw woollen spinning, while worsted prep lends itself to worsted spinning with a short forward draw. But just as there are in-between methods of processing, there are intermediary ways to spin, meaning we can end up with a semi-woollen or a semi-worsted yarn.

We’re going to start by looking at true woollen processing, and move along the scale towards worsted prep.

Rolags and punis

Both rolags and punis are prepared by hand and look like fat caterpillars, which are spun from one end to the other meaning the fibres are perpendicular to the length of yarn. These two preparations are similar, but not the same, and as with a lot of things in spinning there is an in-between that isn’t quite one or the other.

Both rolags and punis are prepared by hand and look like fat caterpillars, which are spun from one end to the other meaning the fibres are perpendicular to the length of yarn. These two preparations are similar, but not the same, and as with a lot of things in spinning there is an in-between that isn’t quite one or the other.

Traditionally rolags are rolled quite loosely with the fingers from a hand carder, and tend to be small, light and fluffy. Punis are much tighter, and better suited to very short fibres like cotton. Again they are typically prepared with hand carders, but are then pulled around a dowel or two while rolling them up to stretch out and compress the fibres, making them rather smoother and more dense.

Recently the term rolag has also started to be used for something that is prepared a bit more like a puni but somewhere in between: a longer sausage of fibre that’s been rolled smoothly round dowels off a blending board or even a drum carder. You’ll often see these coiled up like a snail.

Batts

Batts are large rectangles of carded fibre made on a drum carder – whether it’s a small hand-cranked one or a huge industrial machine. Fleece is fed between the drums with tiny, flexible teeth, which separate out the fibres and make it into a nice, fluffy mat. This gives a true woollen preparation, with the fibres all enmeshed and creating lots of little air pockets. If prepared like this, spinning the batt in any direction will result in a woollen spin.

But it’s also quite common to blend pre-prepared combed top (see below) on a drum carder by layering streaks of fibre on to the top of the big drum, which creates a batt with more aligned fibres. This can then be spun end to end – along the length of the fibres – for a more worsted style spin, or side to side for woollen spinning.

Rolled up, a batt can look like a much bigger rolag, and like a rolag can be spun in this format. But you can also unroll batts and tear or split them to place colours and fibres as you choose.

Sliver

Sliver is a term usually used by mills in commercial processing. Sliver generally isn’t produced specifically for hand-spinning, as it refers to a continuous strip of fibre in various intermediary stages of processing. ‘Carded sliver’ and ‘combed sliver’ both exist – the key thing is that it doesn’t have any twist.

Roving

What a lot of hand-dyers sell and refer to as roving is likely to actually be commercial top.

Roving is thicker than sliver, and is peeled off a drum carder (either by hand or machine), drafted out and very slightly twisted.

It’s a carded preparation that presents similarly to combed top, but is usually fluffier and bouncier, and contains shorter fibres.

This makes it great for long-draw woollen spinning, for light, airy yarn.

Combed top

Proper combed top for true worsted spinning is prepared by hand from locks of fleece on wool combs, with all of the fibres aligned, and not just parallel but with each staple in the same direction. If you imagine an individual wool strand growing on a sheep, the butt is the end closest to the animal’s skin, with the tip on the outside catching the sun. If you draw an arrow from butt to tip, in hand-combed top the arrow of every staple would point in the same direction along the length of the yarn.

Commercially processed wool top is probably the most widely available fibre preparation for hand spinners. You’ll often see it rolled up into big balls or bundles or, the favourite of hand-dyers, made up into pretty braids to show off colour changes and protect the un-spun fibres in storage. Braids, rather than being actually plaited, are usually a big crochet chain, which means you can unravel them bit by bit as you spin.

Commercial top is a little less organised and smooth than hand-combed top, because this perfect alignment is prohibitively time-consuming on a large scale. Commercial top is sliver that has been gilled and combed, processes which remove shorter staples and vegetable matter, align the fibres and draft them out to an even thickness.

Top can be spun with a variety of methods, whether end to end with short forward draw, compressing and smoothing for a worsted yarn, or ‘from the fold’ for a woollen yarn. The main limitation for producing top is that it requires a much longer and more consistent staple length than woollen methods. Certain fibres and blends therefore aren’t suitable for a worsted preparation.

Which fibre preparation should I choose for spinning?

There are so many ways to prepare fibre for hand-spinning, and while some lend themselves to specific methods and styles of spinning, many are quite forgiving and can produce beautiful yarn no matter how you choose to work with them. When you’re learning to spin, experimenting is a huge part of the fun, and as you gain experience you’ll often find which formats you enjoy the most.

Marina is an enthusiast of slow textile crafts, as well as a yarn dyer and knitwear designer.

Using local fibres wherever possible, she’s been spinning yarn by hand for almost a decade and believes in learning by experimenting.

She works from her home in a small rural village in the South-West of England. Find her yarn and patterns at www.marinaskua.com, and follow her projects on Instagram and podcast on YouTube.

Leave a comment

Comments will be approved before showing up.

Also in Blog

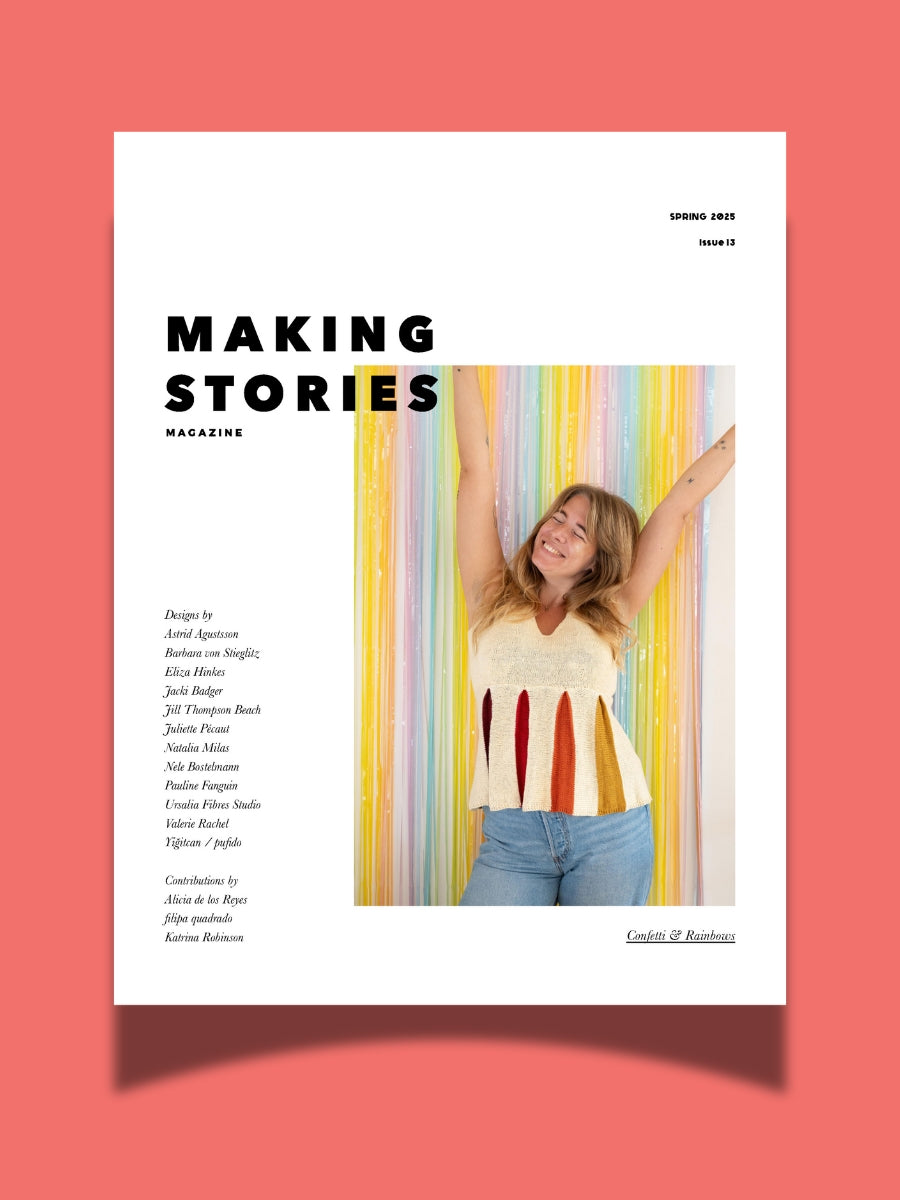

Issue 13 – Confetti & Rainbows | Official Pattern Preview

February 12, 2025 13 min read

Hi lovelies! The sun is out here in Berlin, and what better day to talk about one of the most joyful issues we've ever done than a brilliant sunny winter day – meet Issue 13, Confetti & Rainbows!

In Issue 13 – our Spring 2025 Issue – we want to play! Confetti and rainbows, unusually and unconventionally interpreted in 12 new knitwear designs – a journey through color, shapes, texture and materials.

Confetti made out of dried flowers, collected over months from bouquets and the road side. Sparkly rainbows, light reflecting. Gentle textures and shapes, echoing the different forms confetti can take. An unexpected rainbow around the corner, on a brick wall, painted in broad strokes.

New Look, Same Heart: The Story Behind Our Delightful Rebrand

January 16, 2025 4 min read 1 Comment

Hi lovelies! I am back today with a wonderful behind-the-scenes interview with Caroline Frett, a super talented illustrator from Berlin, who is the heart and and hands behind the new look we've been sporting for a little while.

Caro also has a shop for her delightfully cheeky and (sometimes brutally) honest T-Shirts, postcards, and mugs. (I am particularly fond of this T-Shirt and this postcard!)

I am so excited Caro agreed to an interview to share her thoughts and work process, and what she especially loves about our rebrand!

Thoughts on closing down a knitting magazine

November 19, 2024 12 min read 1 Comment

Who Is Making Stories?

We're a delightfully tiny team dedicated to all things sustainability in knitting. With our online shop filled with responsibly produced yarns, notions and patterns we're here to help you create a wardrobe filled with knits you'll love and wear for years to come.

Are you part of the flock yet?

Sign up to our weekly newsletter to get the latest yarn news and pattern inspiration!